CONSERVE

Artist Engineering’s founding tenet is preventative conservation. The hardware provides an entirely non-contact handling system for works of art in transit: from shipping through to installation, the artwork is securely packed, shipped, staged, installed, and completely untouched.

ADAPT

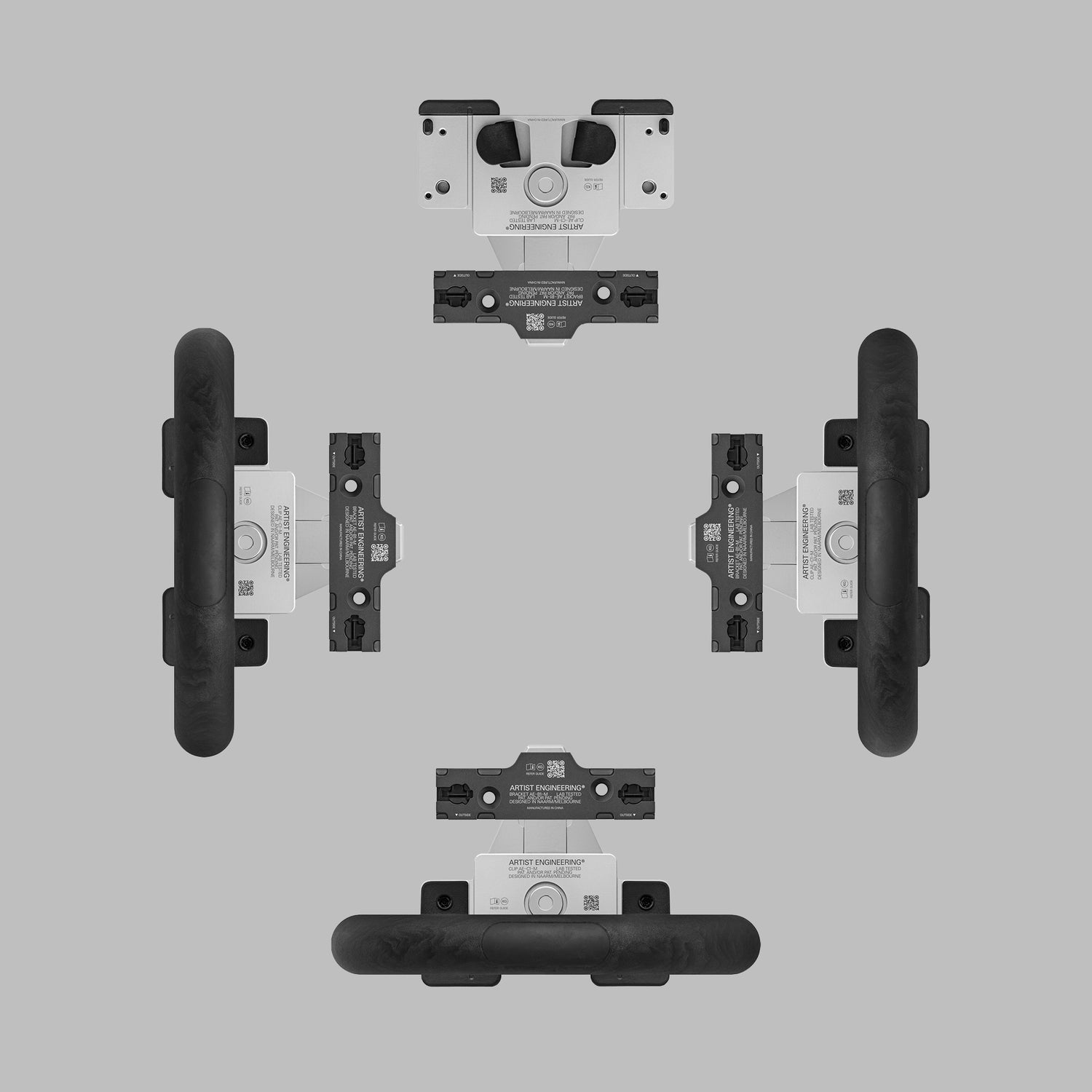

AE Hardware is universal. There are no top, bottom, left or right versions of components. Ordering and installation are simple: you will never have too many lefts and not enough rights. You can’t install components upside down.

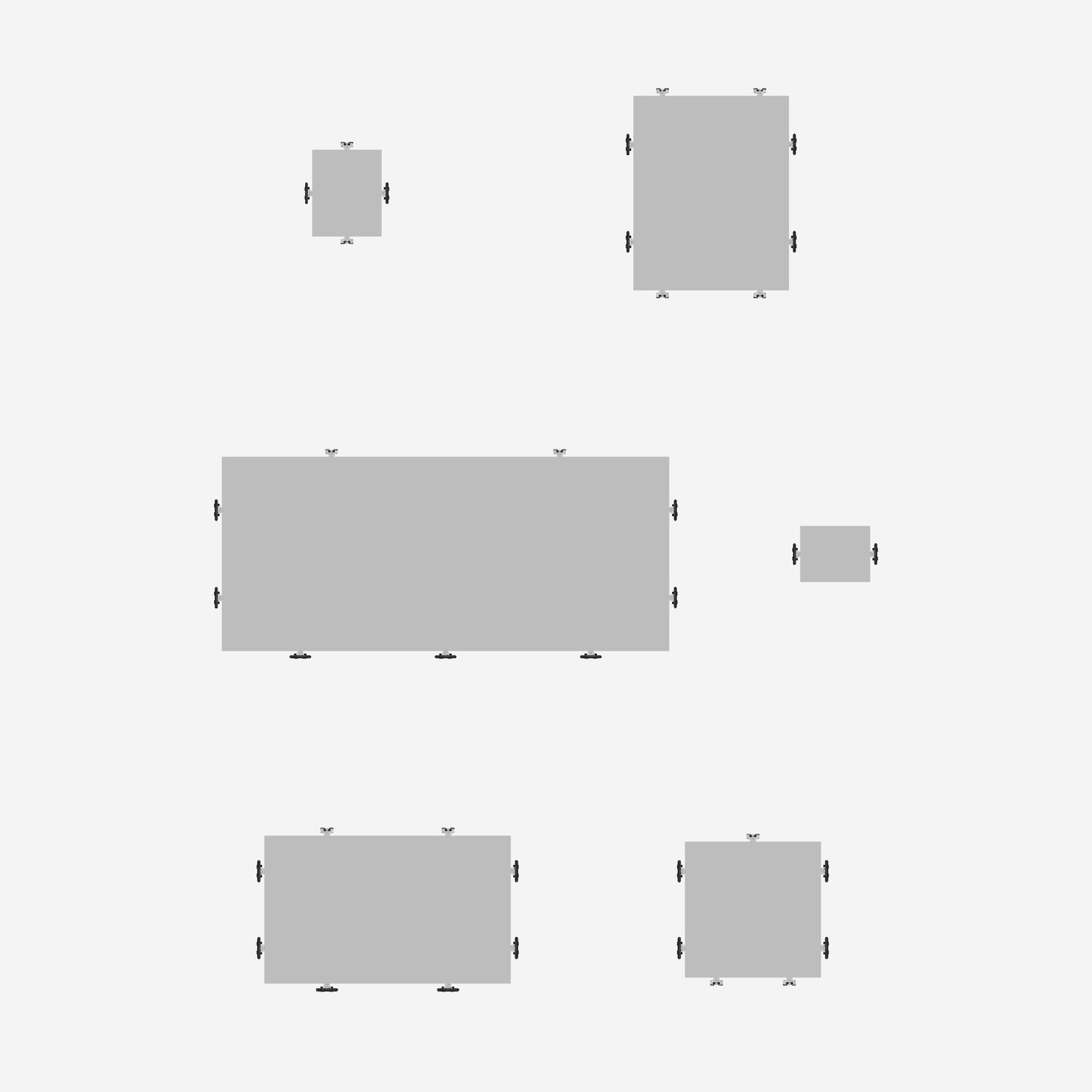

CONFIGURE

AE Hardware can be applied to artworks of variable sizes, proportions and weights. AE Brackets provide compatibility with a wide range of 2D artworks, framed and unframed. Hardware can be retrofitted to existing artworks or installed on stretchers/frames before new works are created.

TEST

In consultation with an international group of mechanical engineers and conservators, Artist Engineering conducted a comprehensive program of laboratory and practical tests to validate the range of static and dynamic loads borne by the hardware. The resulting Load Testing Report provides users with a rich knowledge base to inform their application of the hardware.

EASE

AE Grips provide ergonomic gripping points, reducing the physical strain of handling artworks and the associated risk of injury to handlers. By mitigating the risk of damage to the work, the hardware also eases the psychological stress of handling invaluable objects.

ENDURE

The AE Bracket is a single, universal attachment that combines all the functions typically requiring multiple fixtures. Its open connectivity to a range of accessories makes it future-proof and reduces the need for additional drilling into art objects.

BRACE

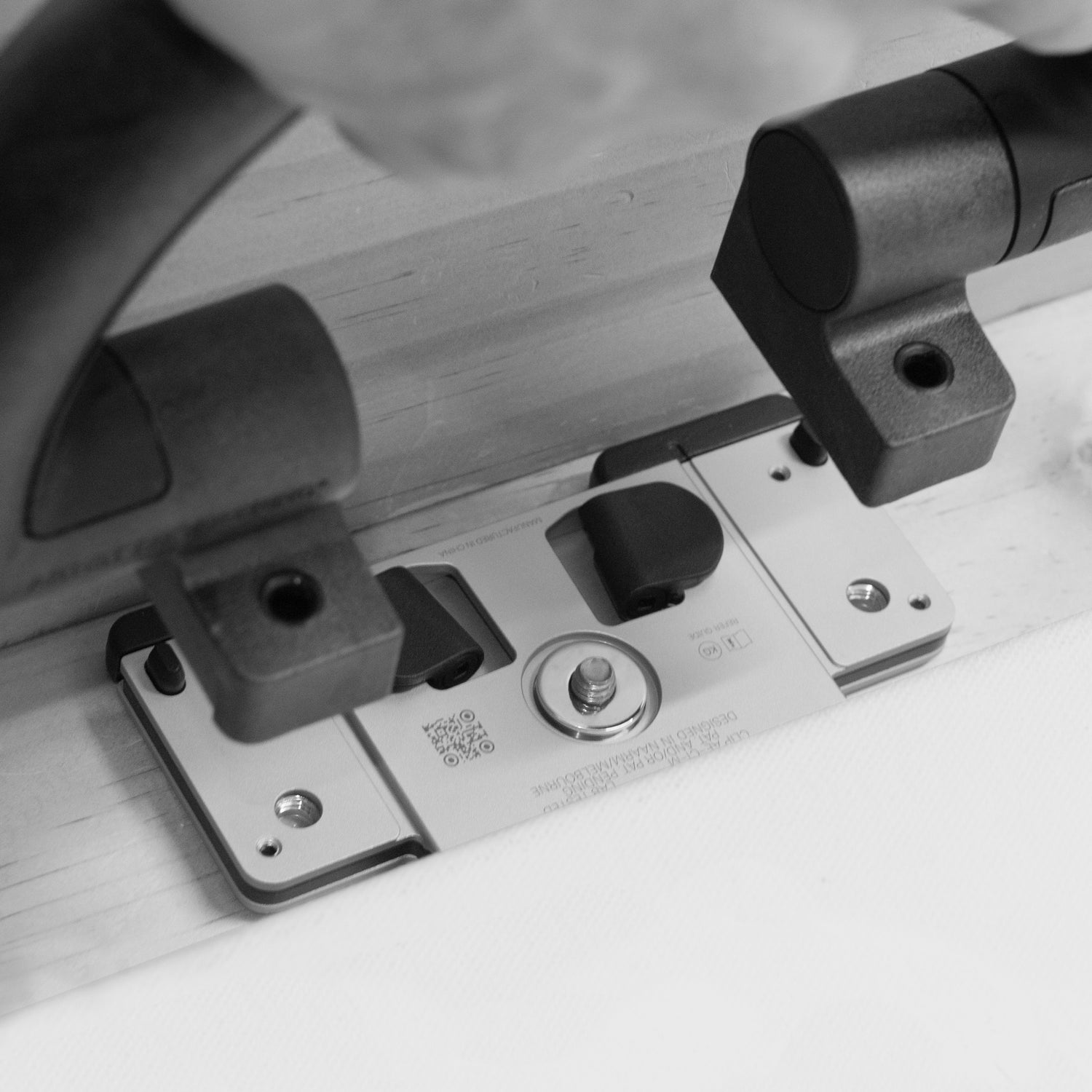

The strength of common folding shipping attachments is limited by the pin connecting the two arms at their pivot point. Crating loads on AE Clips are distributed across a solid piece of Japan-sourced steel, the specific grade and hardening of which were developed over 12 months of iterative prototyping and laboratory testing.

FLOAT

AE Clip eyelets have ~4 mm (~3/16 in.) of “float” and a conical lead in from the reverse. Artworks slide effortlessly over bolts in the travel frame, even if registration is imperfect or bolts are not precisely perpendicular.

NO GLOVES

Users do not need to wear gloves to handle works fitted with AE Grips. The open loop form keeps fingers and palms well away from the artwork surface in all handling positions. This means less reliance on single-use nitrile or cotton gloves and a subsequent reduction in waste.

NO BLOCKS

AE Clips also function as “feet” to elevate the work during staging. This means no blocks, which means nothing is in contact with the base of the work. There’s also no need for a second or third set of hands to follow the work around and make sure blocks are in the right places. It also means a reduction in the use of disposable polyethylene foam.

NO WASHERS

AE Clips have both flat and spring (lock) washers integrated within the eyelet assembly. There is no need to install any washers whatsoever when fastening AE Clips to travel frames. All you need is a regular nut. This eliminates the difficult task of installing two washers over a bolt in a confined space. It also prevents the common occurrence of nuts shaking loose during transit due to missing or incorrect washers.

SHARE

For collection management, or travelling groups of works, AE Grips can be shared between multiple artworks, reducing the cost of hardware ownership and the environmental impacts of manufacturing more things.

INTUIT

AE Hardware was five years in research, development and testing partly because simplicity is difficult to achieve. Most people know how the system works just by looking at it. User error has been designed out — it is difficult to use incorrectly.

OFFSET

AE Bracket countersinks are positioned off-center to avoid two screws being placed along the same grain line, reducing the chances of splitting the wooden supports into which they are fastened.

HIDE

The profile of an AE Bracket is ~6 mm (~15/64 in.) so the artwork can be installed close to flush against the wall. AE Bracket surfaces have been anodised in a neutral, dark grey to match the colour of (most) shadows. They are made to disappear.

FIND

Discreet circular registration marks on the AE Bracket help users to align the correct aperture for AE Clip insertion. They are inconspicuous when you are not looking for them, but easy to find when you are. These marks are laser etched into the aluminium substrate; they will never chip off.

HANG

AE Box-Rings make every AE Bracket a potential hanging point, eliminating the need for additional fixtures. AE Box-Rings provide adjustability on both horizontal and vertical axes, allowing for precise levelling adjustment without re-drilling the installation wall. AE Box-Rings have a “hard stop” at 90°, so they will never fall flat during install. They are under constant friction, so they retain the angle they are set to (0–90°).

RACK

AE Rack Hooks click into AE Brackets, providing a single, artwork-mounted hanging fixture — eliminating the need for a second corresponding rack-mounted fixture. Once the work is installed, AE Clips and AE Grips can be disengaged — allowing hardware to be shared between works across a collection, which means buying less things.

DRIVE

The AE Nut Driver features a magnetic tip in the socket that holds the nut in place during crating (when you’re lowering it onto the bolt) and uncrating (when you’re extracting it). This eliminates the often impossible task of fastening and unfastening wing nuts within a confined space, and increases available torque to ensure nuts are fastened securely.

GLIDE

A 0.3 mm (< 1/64 in.) layer of PTFE (Teflon®) is applied to the reverse of the AE Clip, so it will never scuff the paint of the installation wall. Users can plant the AE Clip hard against the wall to help align it with the AE Bracket and guide it into engagement.

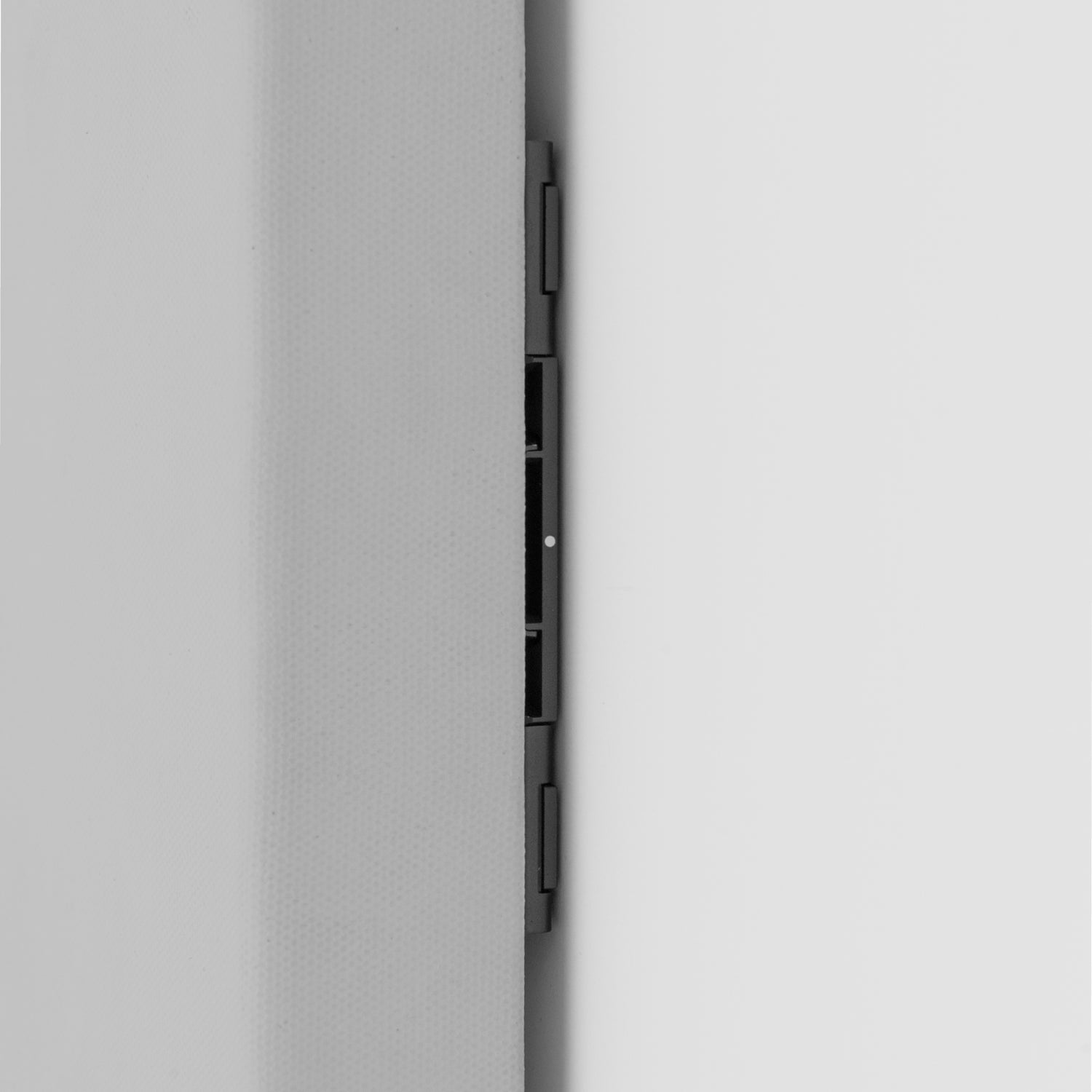

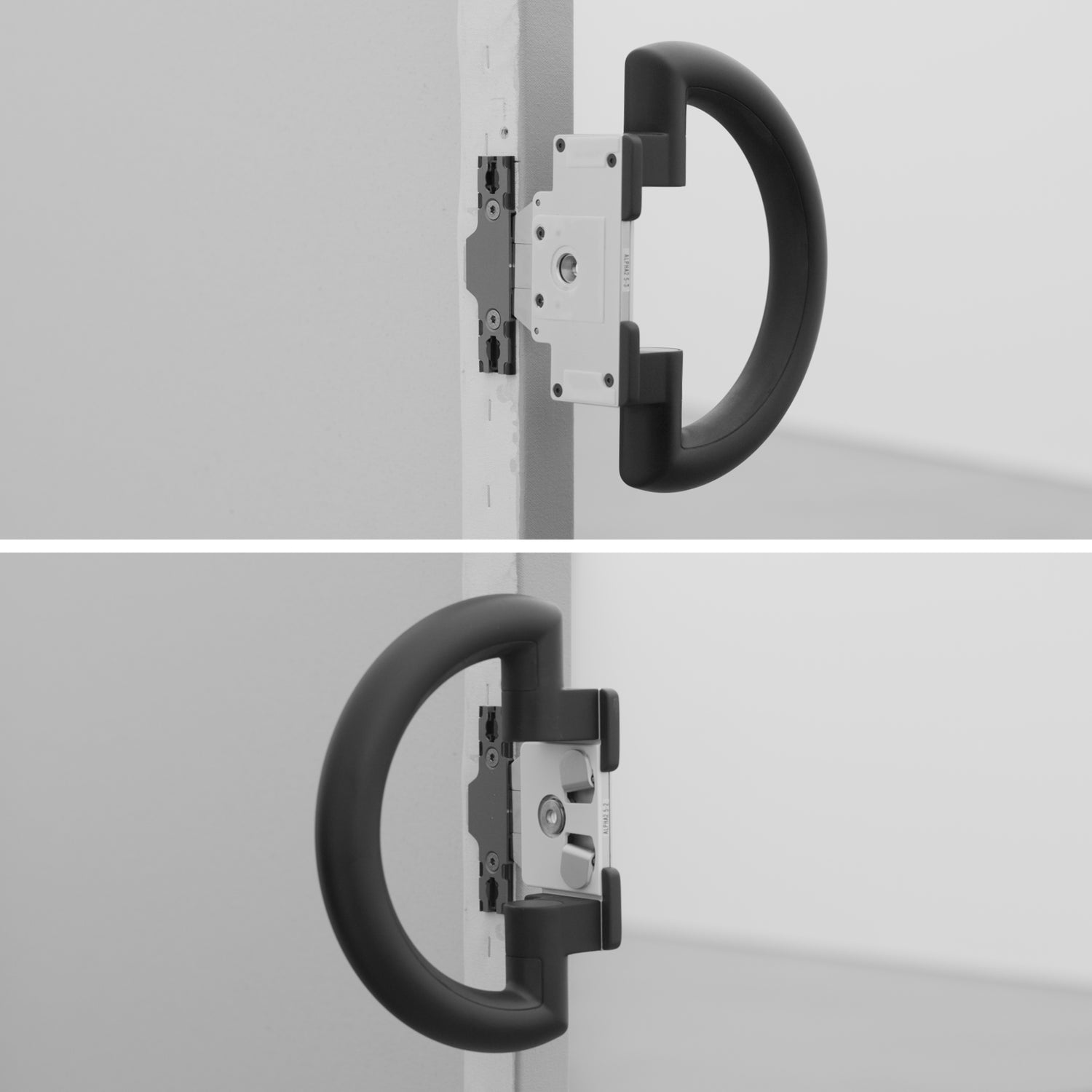

“CLACK”

Spring-loaded catches securely retain the AE Clip in the AE Bracket and provide a firm audible and tactile “clack” on complete engagement, signaling to the user that the hardware is fully secured.

LOCK

Triggers in the AE Clip can fold flat, locking the engagement mechanism and preventing accidental release.

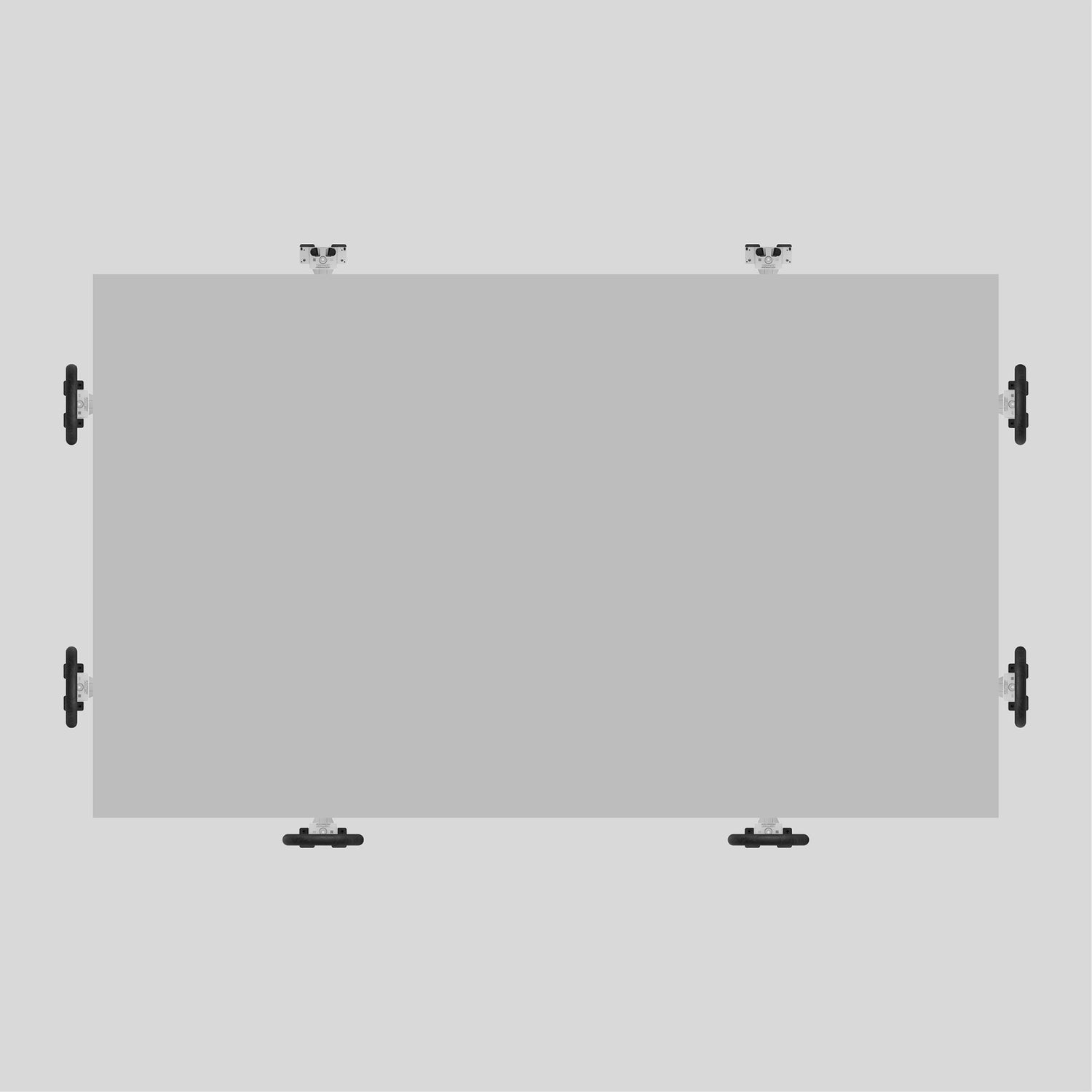

FIT

AE Hardware fits within standard travel frame clearances (~150 mm (6 in.) height × ~75 mm (3 in.) width). For pre-existing works, this reduces the requirement to construct new travel frames. For new works, this means smaller overall crate volumes for shipping and storage.

BASE

AE Grips can be installed as lifting points along the base of an artwork. This makes installing large-scale landscape-oriented works easier and safer, where multiple handlers may be needed across the base.

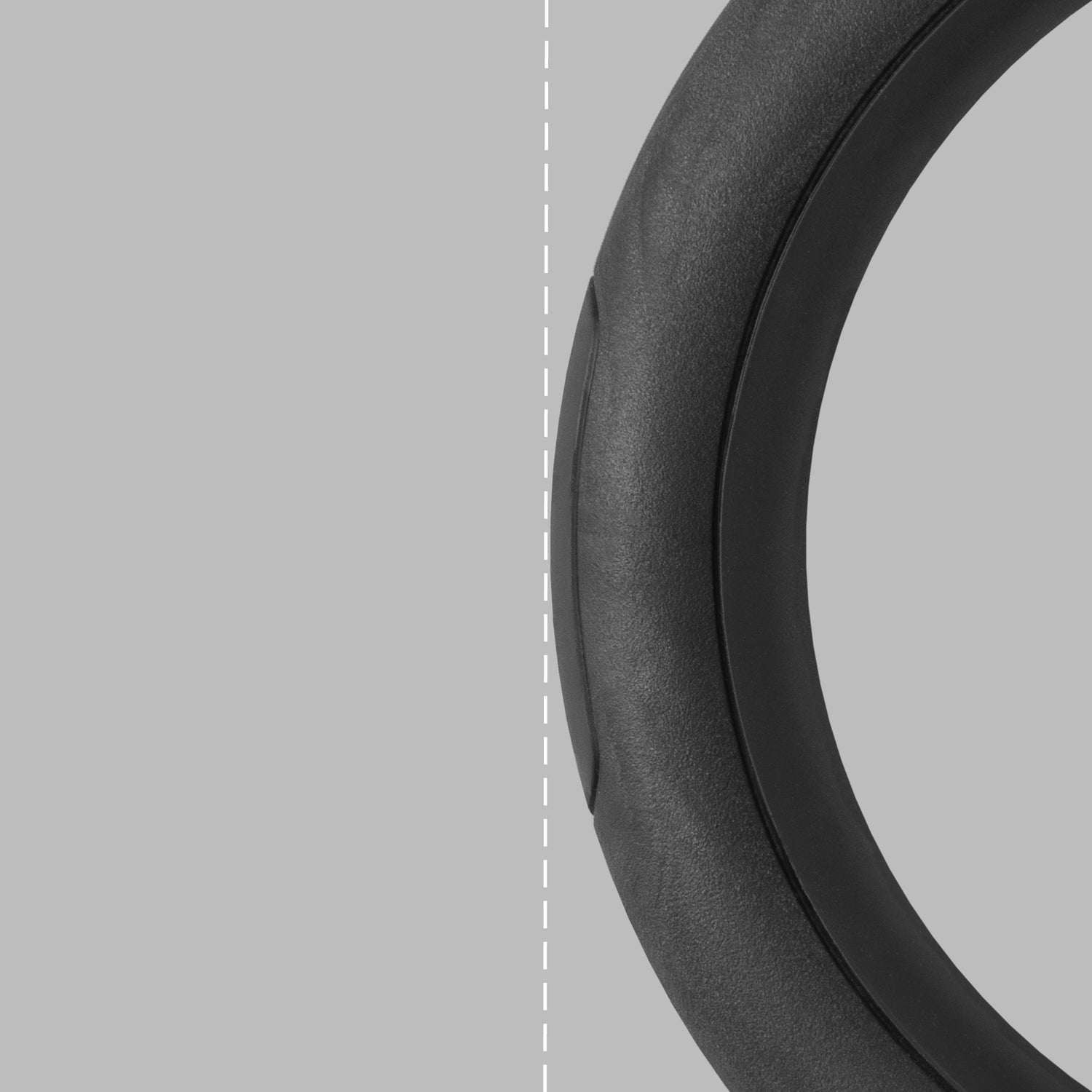

FORM

AE Grips feature an “egalitarian” open-loop form. Handling is comfortable everywhere; no single position is favoured over another. It’s also easy to change hand positions when you need to. The open-loop extends just past semi-circular form, providing additional comfort in critical load-bearing positions.

LIFT

AE Grips make heavy artworks feel lighter — they are 28 mm (~1 1/8 in.) in diameter, the same as an Olympic barbell, and the inside edge has a soft-touch surface for increased cushioning and grip.

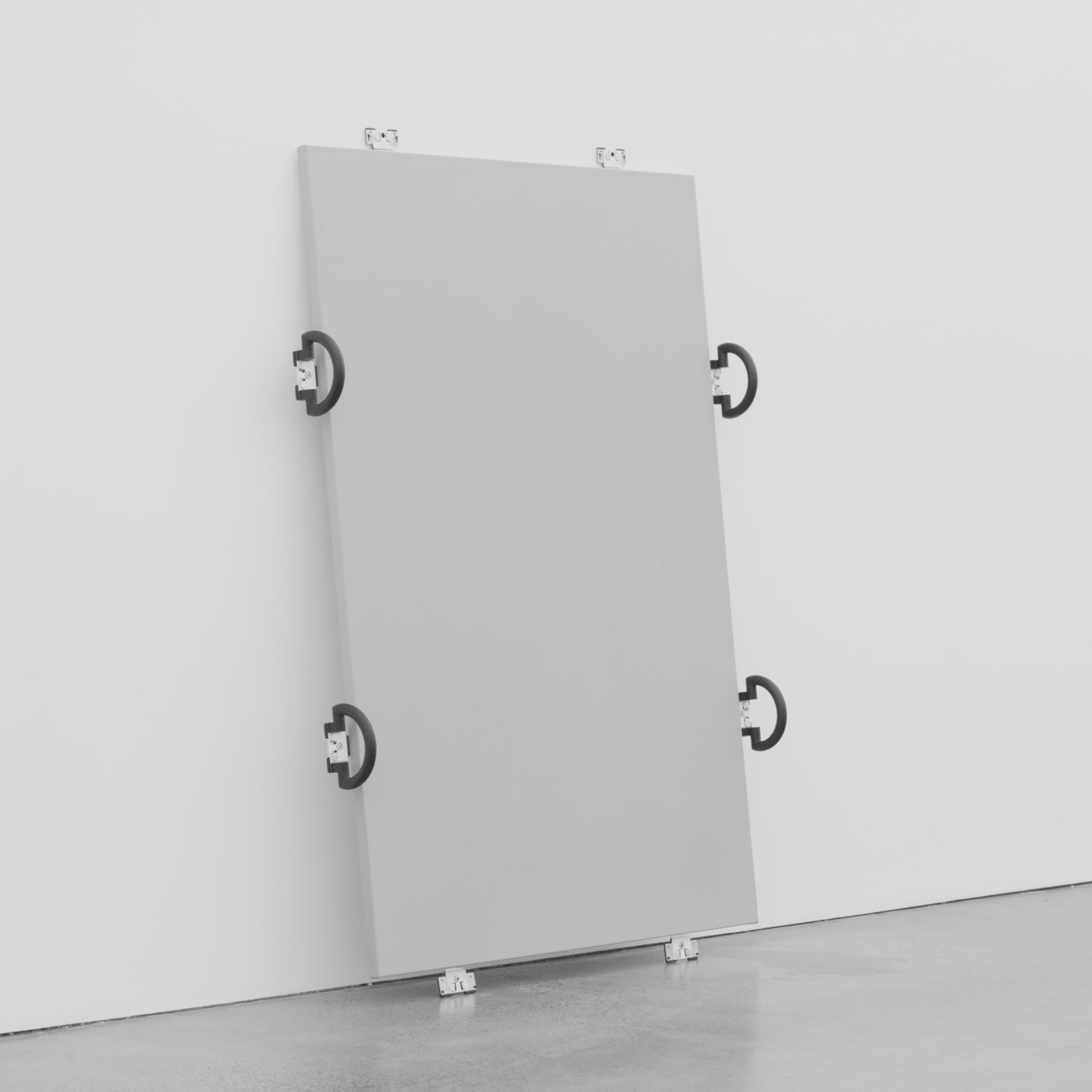

LEAN

AE Clips installed along the top of the artwork provide non-marking contact points with the installation wall during staging, avoiding the need for polyethylene foam pads between the work and the wall.

REST

AE Grips feature a non-marking contact patch to rest artworks face-in against the installation wall during staging, protecting the surface of the object while the exhibition space is being prepared.

REVERSE

AE Grips can be engaged into AE Brackets in reverse. This is useful for removing artworks from frames, or for more discreet handling when presenting works at auction.

STORE

AE × Crumpler Crate Bags provide secure storage for AE drivers and accessories. They are also useful places to store nuts between install and deinstall. An aluminium bracket, stitched through the entire reverse panel, is fastened to the outside wall of the travel frame via four countersinks. The Bag fits within the standard ~50 mm (2 in.) of clear space between the travel frame and crate wall and is accessible from the top.

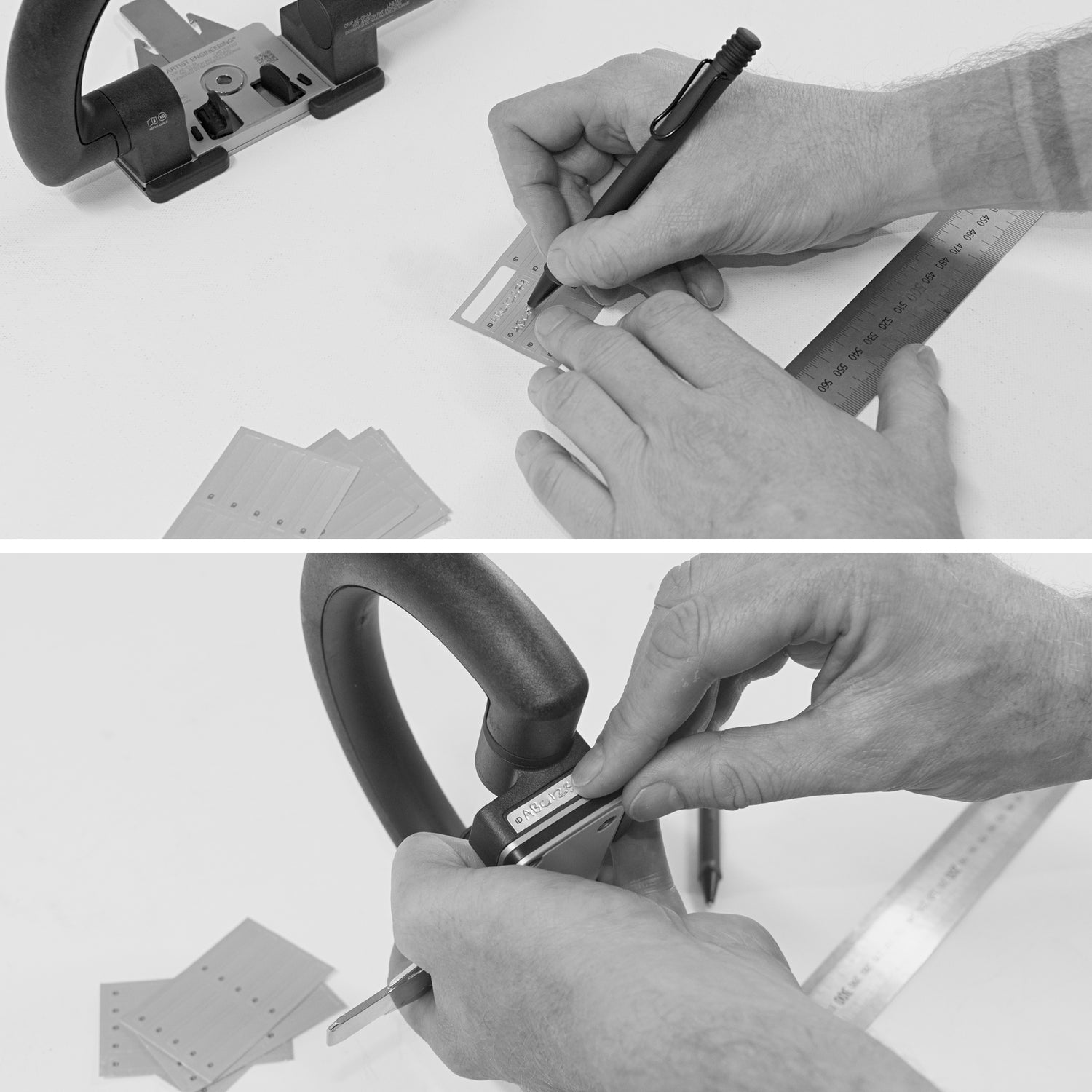

LABEL

Deboss aluminium labels mark AE hardware with corresponding artwork identifiers (accession numbers, for example). The surface of the labels records the ink from a pen and the aluminium substrate takes a permanent impression (deboss), so labels can’t rub off.

INSTRUCT

Every AE Clip and AE Bracket is laser-etched with a QR code linking to our user guide page. Wherever the hardware is, the instructions are, too.